Why everything is going to be more expensive

Have you noticed your bills increasing lately when you go grocery shopping? Have you also been noticing that almost all online stores have a disclaimer about delayed shipping warning that your products might not arrive on time?

If you're feeling the pinch, you're not alone – prices have been increasing, and we foresee that everything is going to be more expensive in the coming months. From groceries to contractor work to new furniture purchases, everything, including promotional products, are going to be affected, and we're going to talk about it in detail.

Table of Contents

Why is everything getting more expensive?

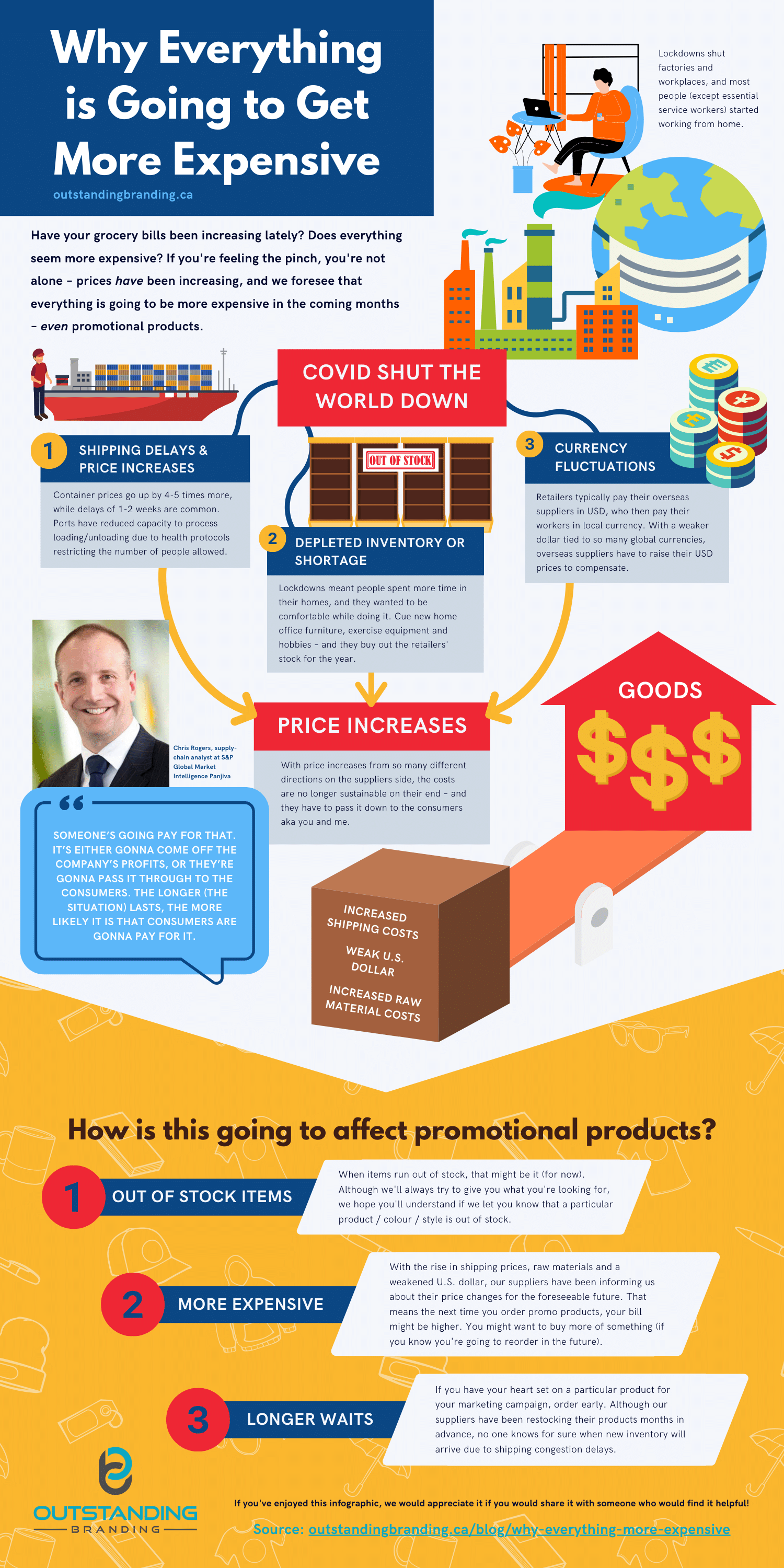

Let's first address the elephant in the room: The COVID-19 pandemic.

1. The Pandemic

The pandemic is the first and most obvious reason for the price hike in so many things. But there's a deeper and more nuanced reason for why prices are going up, and that’s tied to the way our logistics and supply chains are structured in the global economy.

When the pandemic started last year in 2020, everything was shut down. People started working from home, and offices were closed. Cities and countries went into lockdown, and borders were closed.

With more people working from home, remote workers realised they needed to redecorate their living spaces to make it more conducive for office work. People started buying new desks, ergonomic chairs and web cameras for their virtual meetings.

When the gyms closed, people needed a way to work out. Without access to the equipment in the gyms they used to go to, they started buying everything from new Peloton bikes to dumbbells, yoga mats, bicycles and more.

The global lockdown not only affected office workers, but also critical supply chain workers such as dock workers, delivery drivers, and logistics coordinators in the logistics industry.

With the new social distancing guidelines, there was also a decrease in the number of workers available on site to load and unload containers, despite the increase in the number of vessels being processed daily.

In February 2021, there were 31% more ships and 41% more containers coming into the Port of Los Angeles, the largest port in North America. Despite container production at an all-time high, ships are still having to wait an average of 1-2 weeks to get into ports.

All these factors affected the “unloading and distribution of goods made at factories in Asia and arriving by ship to North America and Europe,” which ultimately caused delays in delivering goods to consumers on time.

In the case of Peloton, they’re spending $100 million to air freight their bikes and treadmills from Asia to the United States, spending over ten times their normal shipping costs to expedite customer deliveries and deal with shipping delays. Although retailers have been bearing the costs for now, these additional expenses will eventually trickle down to the consumer.

Chris Rogers, a supply-chain analyst at S&P Global Market Intelligence Panjiva said:

“Someone’s going pay for that. It’s either gonna come off the company’s profits, or they’re gonna pass it through to the consumers. The longer (the situation) lasts, the more likely it is that consumers are gonna pay for it.”

2. Depleted/reduced Inventory

The increased spending from consumers meant retailers had their inventory depleted early on during the year. Retail chains usually make a big buy to restock their goods for the year, and in recent years, have relied on overseas manufacturers with the cheapest costs such as China, Vietnam and India. Despite the pandemic, China accounted for $47.08 billion worth of imports into Canada in 2020, compared to $44.5 billion in 2019.

When China went into lockdown in January 2020, their manufacturing sector came to a screeching halt. That paralysed the flow of all kinds of goods being exported – “from strollers, gym clothes, Nintendo Switch consoles, and crucial components for products assembled in other countries, such as textiles for clothing and parts for cellphones and computers”. In particular, the automakers have been crippled by “a shortage of computer chips — vital car components produced mostly in Asia. Without enough chips on hand, auto factories from India to the United States to Brazil have been forced to halt assembly lines.”

Even when China reopened their factories after regaining control of the pandemic, shipment of their goods on massive cargo ships were delayed by logistical nightmares. The increasing lack of labour as hundreds of thousands of workers are stranded at sea due to global pandemic travel restrictions doesn’t help either.

In the meantime, the rest of the world, which supplies the rest of the imported goods sold in North America, had yet to return to full manufacturing capacity, which leaves retailers and suppliers in a bind.

3. Currency fluctuations

When the pandemic first started in China, expectations about China’s economic growth tumbled. The province was the first to shut down with domestic and international air travel high restricted. The yuan continued to weaken through to the end of May 2020, until China made progress in containing the spread of the virus and their economy rebounded.

At the same time, the US dollar started falling as the virus ran rampant through the country. Our suppliers typically pay their global vendors in USD, who then primarily pay their workers and suppliers in their local currency. With the weakened dollar tied to many global currencies, global vendors are having to raise their USD prices to compensate for the weakened U.S. dollar.

Source: CME Group, “COVID-19’s Influence on Exchange Rates”

How does this affect promotional products?

While we’ll do everything we can to make sure you get what you want at the time that you need, here are some potential issues that we could face in the upcoming half of 2021.

1. Inventory shortage

With the upcoming back-to-school season and the yearly holiday rush, inventory shortage is likely to be common. We have already been seeing low to no availability on certain products, and this is likely to become common across the board as more suppliers run out of stock while waiting for incoming products.

2. Price increase from suppliers

With the increase in prices for shipping and the fluctuations in global currencies, our suppliers are having to pay their vendors more for products. Although they have been absorbing the costs throughout this past year, many of them have informed us that they’ll be increasing their prices from as early as August 2021 to January 2022.

3. Longer wait times

Although our suppliers have been restocking their inventory months in advance, port congestion is still causing shipping delays. When the available stock runs out, there is usually an estimated date of new product arrival, which is subject to change. This means that you may not receive your goods in-hand on the promised date, due to the delay of incoming inventory.

What can you do?

Knowing what we do, here are some solutions we have for your promotional marketing needs.

1. If you know you’re going to need more, buy more now

If you’re on the fence about the number of products you’ll need and you know you’ll definitely be needing more, we highly recommend purchasing more while stock is still available.

We’ve personally experienced this with our own self-promotional products – planning out a marketing campaign only to find out that the product would only be available several months later.

During these times, it might take up to several months due to shipping and manufacturing delays before the inventory is back in stock.

In addition to the upcoming price increases announced from our suppliers, buying more now would help you save costs on products you know you’ll need in the long run.

2. Buy Made in Canada

With the delays in inventory being restocked and the upcoming price increases, another solution to your promotional products problem is to purchase products made in Canada instead. Since these products are made domestically, you won’t have to worry about overseas shipping delays causing inventory issues.

Purchasing Canadian made products also supports our local economy and businesses, which is something we strongly believe in. Some amazing brands we recommend are:

Attraction

Botanical Paperworks (female-owned, local Winnipeg business)

3. Plan ahead

It may be a hot July summer, but we’re already planning ahead for our holiday gifts to our staff and customers.

Gifting clients a thank you gift at the end of the year is a great way to strengthen existing and develop new client relationships, and this year will be no different.

Inventory availability is a hard thing to guarantee these days, and there may be potential delivery delays in the lead up to the holiday season. By ordering earlier, you’ll be able to secure what you need and not have to worry about potential item unavailability.

We highly recommend planning ahead and making your orders as early as you can, if you don’t want your products to be stuck “in transit” or have to change them for something else!

4. Be patient

If you have your heart set on a particular product and are willing to wait for it to come back in stock, being patient is the only way to go. While we’ll do our best to get you everything on time, the restocking dates provided by our suppliers are only a estimated date. Shipping delays could cause the product to come in later than expected.

And that’s it!

This article was a monster to write, but we hope it’s helped educate you on the shipping delays and inventory issues of the world and how it’ll affect the promotional product industry.

If you’ve found this article useful, please share it with another person that you think will find helpful!

We’ve also created a handy infographic (on the right) that you can share if you’ve found it helpful.

![[Case Study] Tristar’s 10th Anniversary Thank You Package](https://images.squarespace-cdn.com/content/v1/5e3af04073fa6516daf9bd45/1622731128144-ZMGKUK55IFKSY3QFEN4B/21-06-02+Tristar+Case+Study+Blog+Pinterest.png)